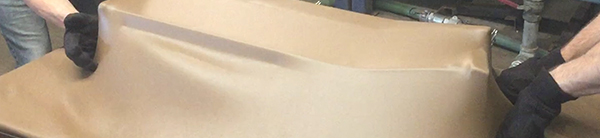

When it comes to creating premium products with a luxurious touch, vinyl coated thermoformed products stand out as an exceptional choice. The combination of thermoforming technology and vinyl coating brings forth a remarkable blend of aesthetics, durability, and a tactile experience that exudes luxury. In this article, we will explore the unique characteristics and advantages of vinyl coated thermoformed products that deliver an unparalleled luxurious feel.

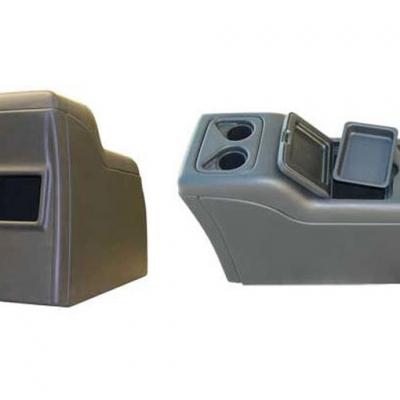

Unparalleled Aesthetics: Vinyl coating adds a layer of sophistication to thermoformed products, enhancing their visual appeal. The smooth and sleek surface of vinyl-coated parts creates a seamless finish, resembling high-end materials like leather or premium upholstery. The wide range of color options, textures, and patterns available in vinyl coatings allows for limitless design possibilities, ensuring that the final product reflects the desired luxury aesthetic.

Supreme Comfort and Soft Touch: One of the standout features of vinyl coated thermoformed products is the luxurious feel they provide. The soft and supple touch of vinyl coating creates a delightful tactile experience, reminiscent of high-quality materials. Whether it's an automotive interior, yacht furnishings, or premium packaging, the luxurious feel of vinyl coating enhances user comfort and elevates the overall experience.

Durability and Longevity: Luxury is not just about aesthetics; it's also about long-lasting quality. Vinyl coated thermoformed products offer exceptional durability, ensuring they retain their luxurious appeal over time. Vinyl coatings provide resistance against scratches, abrasions, and fading, maintaining the product's pristine appearance and extending its lifespan. This durability ensures that the luxurious feel of the product remains intact, even with regular use.

Easy Maintenance and Care: Another advantage of vinyl coated thermoformed products is their ease of maintenance. The non-porous surface of vinyl coatings repels stains and spills, making them easy to clean and maintain their luxurious appearance. Routine cleaning with mild soap and water is often sufficient to keep the product looking fresh and elegant. This effortless maintenance adds to the overall appeal of vinyl coated thermoformed products.

Versatility and Customization: Vinyl coated thermoformed products offer versatility and customization options, allowing designers and manufacturers to create bespoke luxury items. The flexibility of thermoforming enables the creation of intricate shapes and contours, tailored to specific design requirements. Combined with vinyl coating, this allows for the production of unique, high-end products that capture the essence of luxury and exclusivity.

Applications of Vinyl Coated Thermoformed Products: Vinyl coated thermoformed products find applications across various industries that prioritize luxury and sophistication. They are commonly used in automotive interiors, private jets, yachts, high-end consumer electronics, custom furniture, and premium packaging. The luxurious feel of vinyl coated thermoformed products enhances the overall ambiance and elevates the user experience in these settings.

Conclusion: Vinyl coated thermoformed products offer a luxurious feel that combines aesthetics, durability, and comfort. The sleek, soft touch of vinyl coating elevates the sensory experience, providing a high-end feel akin to luxury materials. With exceptional durability, easy maintenance, and customization options, these products embody the essence of luxury across diverse applications. Whether it's in automotive interiors, marine vessels, or luxury packaging, vinyl coated thermoformed products deliver a touch of opulence that resonates with discerning customers seeking the utmost in quality and refinement.